ARKEO

SYSTEM

FABRICANT D’OSSATURE MÉTALLIQUE LÉGÈRE MADE IN FRANCE

Architectes, promoteurs, constructeurs : vous recherchez des solutions innovantes pour limiter votre empreinte environnementale et construire plus rapidement ?

ARKEO SYSTEM est votre partenaire industriel pour faire de vos engagements une réalité.

Avec les ossatures métalliques légères, vous faites le choix d’un matériau alternatif durable, qui répond aux attentes de vos clients et aux nouvelles contraintes réglementaires.

Grâce à notre outil de modélisation 3D compatible BIM, vous intégrez l’acier léger facilement dans tous vos projets, avec une grande liberté architecturale.

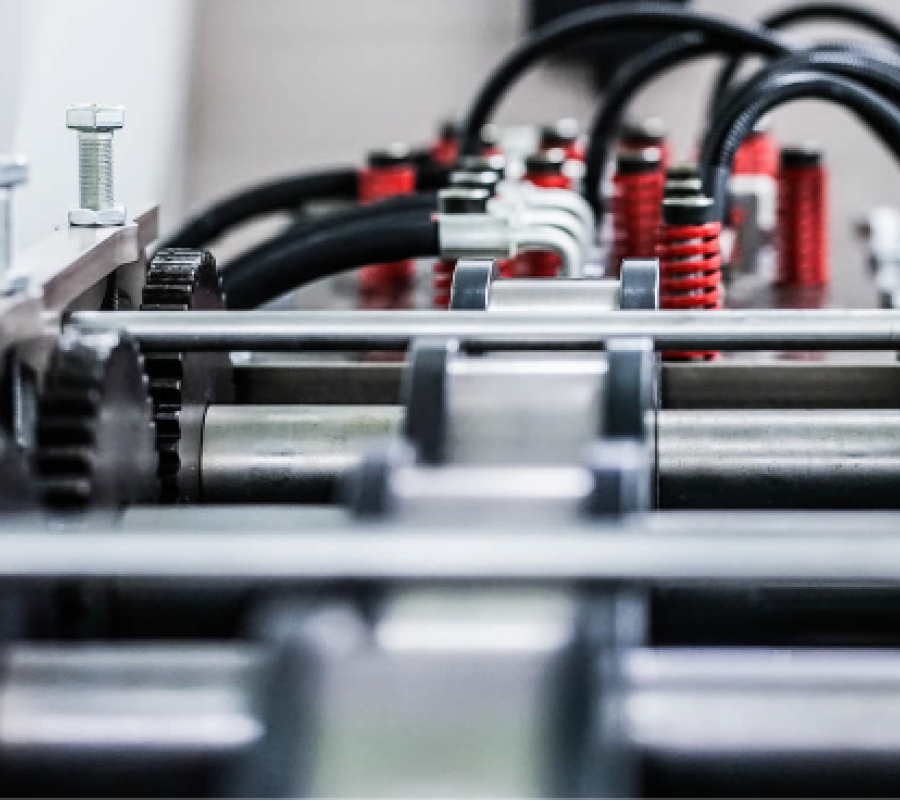

Produites à la demande, assemblées hors-site dans notre usine française et livrées sur votre chantier, nos ossatures métalliques sont la garantie d’une construction rapide, sans gaspillage ni déchet.

Vous souhaitez innover avec l’acier ? Notre bureau d’étude développe pour vous les conditions de la réussite de votre projet. Contactez-nous !